The Engineer’s Guide to Control Valves in HVAC Systems

- marketing96225

- Sep 26, 2025

- 3 min read

Introduction

Control valves are the unsung heroes of HVAC systems. They regulate water or steam flow to maintain temperature, optimize efficiency, and extend equipment life. Choosing and applying the right control valve is essential for performance, energy savings, and system reliability.

In this guide, we’ll break down the types of HVAC control valves, when to use them, and the common selection mistakes engineers should avoid.

What Are Control Valves in HVAC?

Control valves are devices that regulate fluid flow through heating, ventilation, and air conditioning systems. They respond to signals from actuators or building automation systems (BAS) to adjust flow precisely.

Types of Control Valves

1. Two-Way Valves

Function: Allow flow in one direction, modulating open/closed as needed.

Best for: Variable flow systems where pump energy savings are a priority.

Pros: Simple design, energy-efficient.

Cons: May cause system pressure fluctuations if improperly sized.

2. Three-Way Valves

Function: Direct flow between two outlets, either mixing or diverting.

Best for: Constant flow systems or when bypass is required.

Pros: Stable flow, flexible design.

Cons: Can reduce system efficiency if not configured correctly.

3. Pressure Independent Control Valves (PICVs)

Function: Combine control and balancing into one device, maintaining consistent flow regardless of pressure fluctuations.

Best for: Modern energy-efficient HVAC systems.

Pros: Simplifies design, reduces commissioning costs, improves energy performance.

Cons: Higher upfront cost, but ROI comes from energy savings.

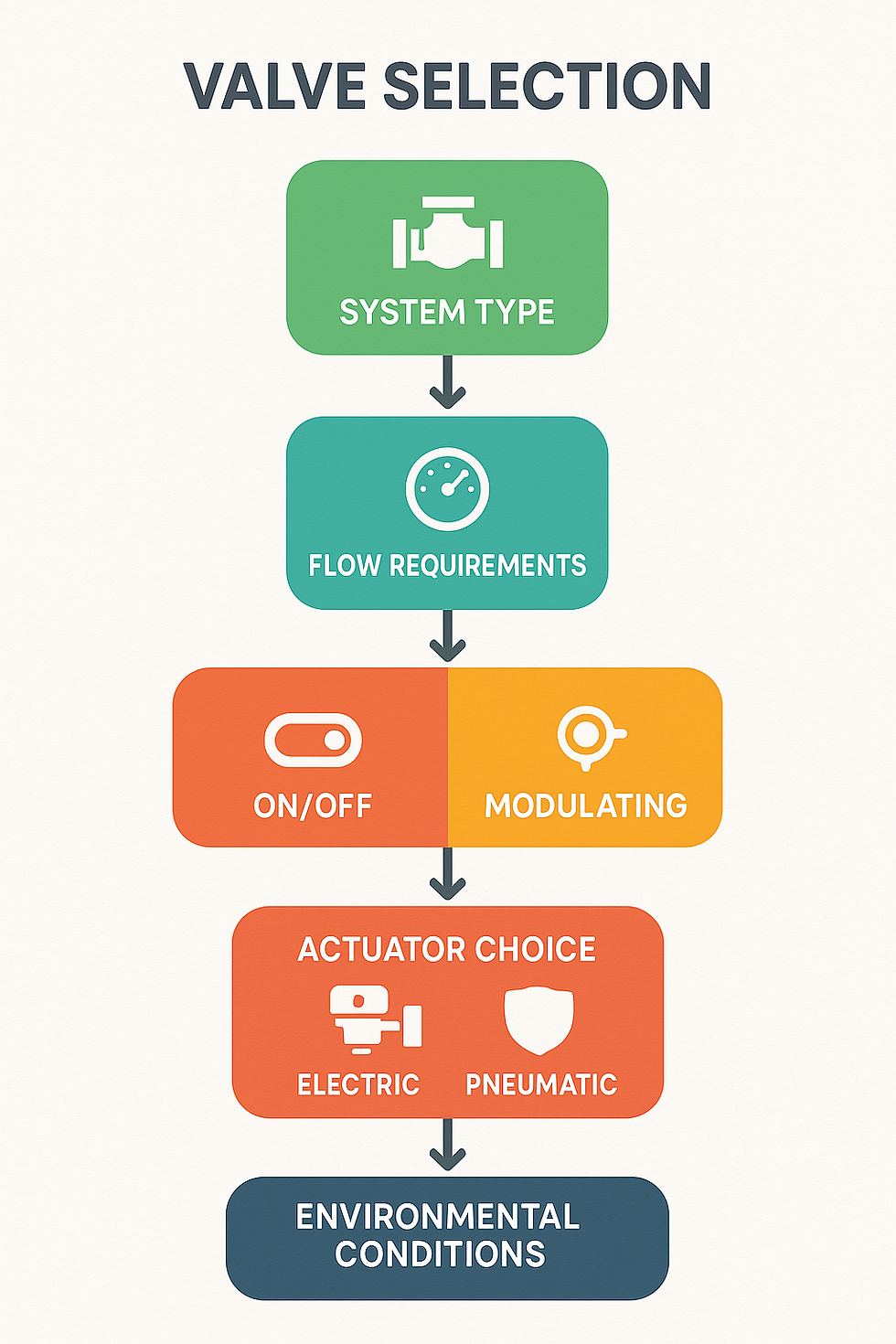

How to Select the Right HVAC Control Valve

Step 1: Calculate Flow Requirements

Use valve Cv (flow coefficient) to match valve capacity to system demand.

Oversized valves reduce control accuracy; undersized valves restrict performance.

Step 2: Determine Control Type

On/Off valves: Best for simple heating/cooling.

Modulating valves: For precise temperature and flow control.

Step 3: Consider the Actuator

Electric actuators → quiet operation, ideal for indoor use.

Pneumatic actuators → reliable in industrial environments.

Keywords: valve actuator HVAC, electric vs pneumatic actuators

Step 4: Match to System Design

Variable vs. constant flow systems.

Direct-return vs. reverse-return piping.

Step 5: Check Environmental Conditions

Corrosion risks → choose brass valves for long-term reliability.

High humidity → ensure proper actuator enclosure ratings (IP/NEMA).

Common Control Valve Issues (and How to Prevent Them)

Water hammer → caused by improper sizing; prevent with correct Cv selection.

Actuator failure → maintain and troubleshoot regularly.

Bypass inefficiency → avoid unnecessary three-way valves in variable flow systems.

Practical Application Examples

Chilled water systems: Two-way valves with variable-speed pumps maximize energy savings.

Hot water heating systems: Three-way valves stabilize flow in constant circulation systems.

Modern green buildings: PICVs for precision control and simplified commissioning.

FAQs

Q: What is the difference between a 2-way and 3-way valve in HVAC?A: A 2-way valve regulates flow by opening/closing, ideal for variable flow. A 3-way valve mixes or diverts flow, better for constant flow systems.

Q: How do I know if I need an actuator?A: Any automated HVAC control system requires an actuator to adjust valves based on BAS signals.

Q: Are PICVs worth the investment?A: Yes—though more expensive upfront, they save energy and simplify balancing.

Conclusion

Control valves are vital to HVAC efficiency, reliability, and comfort. From 2-way and 3-way valves to advanced PICVs, selecting the right control valve ensures system stability and long-term performance.

At Enolgas USA, we provide a wide range of brass valves, actuators, and automation solutions for HVAC and industrial applications. Contact us to learn more about integrating the right control solutions for your projects.

Comments