High-Performance Composite Pipes & Fittings: The Future of PVF Systems

- marketing96225

- Aug 13

- 3 min read

Why Composite Pipes and Fittings Are Gaining Ground in the PVF Industry

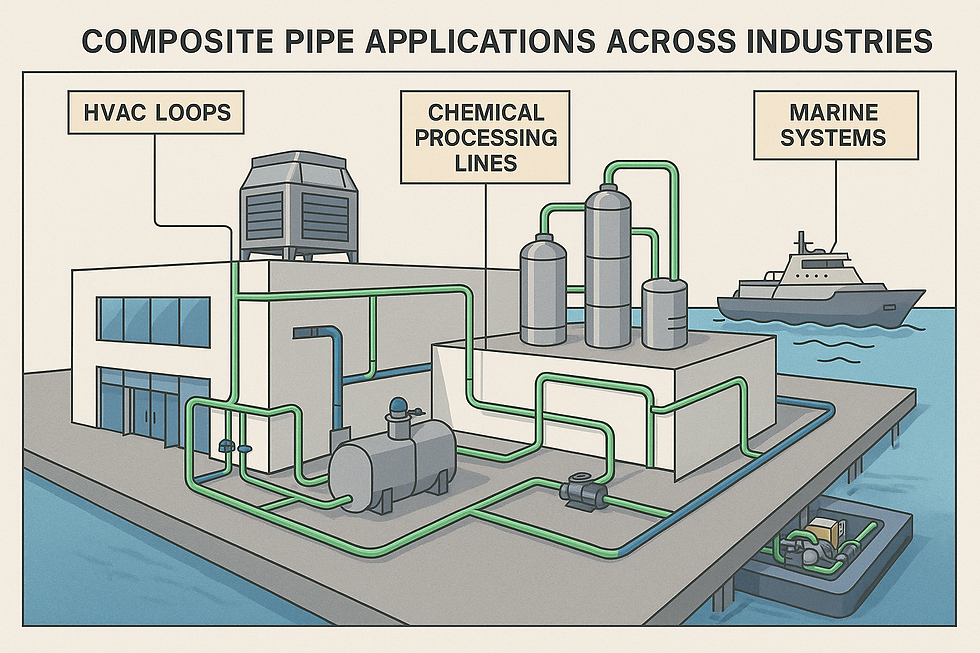

The PVF (Piping, Valves, and Fittings) industry is experiencing a materials revolution. High-performance composite pipes and fittings are rapidly replacing traditional materials like steel, copper, and cast iron in many applications. From HVAC piping to chemical processing plants, these advanced materials offer significant performance, safety, and cost advantages.

By combining lightweight construction with exceptional corrosion resistance, composite piping systems are becoming the go-to choice for engineers, contractors, and facility managers who need reliable, long-lasting solutions.

Key Advantages of High-Performance Composite Pipes & Fittings

Corrosion ResistanceUnlike metal pipes that can rust or corrode over time, composite materials resist chemical degradation. This makes them ideal for chemical-resistant fittings in industrial fluid handling, HVAC chilled water systems, and marine environments.

Lightweight Yet StrongComposite pipes are significantly lighter than steel or copper, reducing handling and installation costs. This is especially beneficial in large-scale industrial piping projects and modular builds where weight savings translate into faster, safer installations.

Thermal and Chemical StabilityWhether transporting hot water in HVAC systems or aggressive chemicals in manufacturing, advanced piping materials maintain their structural integrity across a wide temperature range.

Extended Service LifeHigh-performance composites are designed for decades of use without significant degradation—reducing long-term maintenance and replacement costs.

Advantages of Composites Over Steel in PVF Applications: Composites are lighter, offer excellent corrosion resistance, operate effectively in a wide temperature range of -60°C to 200°F, and have a longer lifespan compared to steel.

Applications Across Multiple Industries

HVAC Systems – Chilled water distribution, heating loops, and condenser water systems.

Industrial Fluid Handling – Acidic and alkaline chemical transfer lines, cooling systems, and process water.

Plumbing Systems – Potable water distribution in commercial and residential buildings.

Marine and Offshore – Saltwater cooling, ballast systems, and desalination piping.

Energy Sector – Geothermal systems, solar heating loops, and district heating networks.

Types of Composite Piping Materials

Fiberglass Reinforced Plastic (FRP) – Strong, corrosion-resistant, and widely used in chemical plants.

Glass Reinforced Epoxy (GRE) – Excellent mechanical strength for high-pressure applications.

Polyvinylidene Fluoride (PVDF) – Exceptional chemical resistance for aggressive fluids.

High-Density Polyethylene (HDPE) – Flexible, cost-effective, and easy to install.

The Role of Composite Pipe Fittings in System Performance

Even the best pipe material can underperform without the right fittings. Composite pipe fittings are engineered for precise tolerances, ensuring leak-free joints, smooth flow transitions, and compatibility with multiple connection types—threaded, flanged, or fusion-welded.

Why the PVF Industry Is Moving Toward Composites

Industry trends are clear: the demand for lightweight piping, modular piping systems, and sustainable materials is growing. Composite pipes and fittings offer the performance characteristics needed to meet modern project requirements while lowering total lifecycle costs.

Bottom Line:

High-performance composite pipes and fittings are no longer niche products—they’re a proven, cost-effective solution for HVAC, plumbing, and industrial fluid handling systems. As the PVF industry moves toward corrosion-resistant piping and advanced piping materials, composites are set to become the new standard.

Comentários