Why Glycol Valve Compatibility Matters in CommercialHVAC Systems

- marketing96225

- 2 days ago

- 3 min read

Commercial HVAC systems in cold climates depend on glycol–water mixtures to prevent freeze‑ups, corrosion, and unplanned downtime. A properly designed and maintained glycol heat‑transfer loop can deliver over 20 years of reliable service, but valve failure—even from minor corrosion or seal degradation—can lead to leaks, system inefficiency, and costly shutdowns.

Ensuring glycol valve compatibility and using the right HVAC antifreeze system valves keeps fluid integrity intact and extends equipment life. (ChemAqua - English US)

What Is Glycol?

Glycol is a class of dihydric alcohols—colorless, odorless, viscous liquids that mix readily with water to depress its freezing point. The two most common types used in HVAC are:

Ethylene glycol (toxic; automotive antifreeze)

Propylene glycol (food‑grade; safer for occupied buildings)

At room temperature, glycol–water solutions can lower freezing points to as low as –60 °F, safeguarding rooftop chillers, hydronic loops, and thermal storage tanks from freeze damage. (EAI Waterh2x Engineering)

Glycol‑Water Mixtures & Fluid Properties

Glycol concentration governs both freeze protection and pumpability:

Burst protection (30 % ethylene glycol / 35 % propylene glycol) prevents pipe rupture during freeze‑thaw but allows slush formation.

Freeze protection (40 – 50 %) ensures fully liquid flow down to the lowest ambient temperature—critical where ice crystal formation must be avoided. (RL Deppmann)

Key fluid properties affected by glycol:

Viscosity: Rises with glycol%, increasing pump energy.

Heat capacity: Drops as more glycol is added, slightly reducing thermal performance.

Corrosion inhibition: Requires compatible inhibitors to protect metals and elastomers.

Chemical Resistance & Valve Material Compatibility

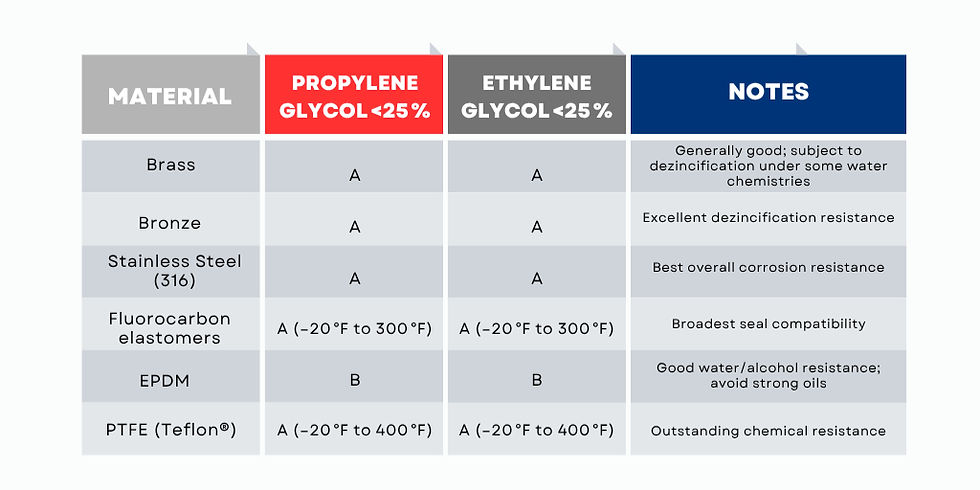

Glycol solutions—especially when mixed with water and corrosion inhibitors—can stress valve materials. Reference chemical resistance guides to confirm compatibility at your system’s maximum temperature and glycol concentration.

Ratings per NIBCO Chemical Resistance Guide: A = recommended; B = conditional; C = not recommended (Howell Pipe)

Dezincification Considerations

Brass valve bodies, though cost‑effective, can undergo dezincification—selective zinc leaching that weakens the metal and clogs passages. To prevent this:

Specify dezincification‑resistant brass (DZR) alloys or forged/annealed C27450 grades.

Consider bronze or stainless steel bodies in systems with aggressive water or extended glycol exposure. (AMPP)

Valve Selection Best Practices for HVAC Antifreeze Systems

Valve Type:

Ball valves (full‑port) for tight shut‑off and minimal fluid trapping.

Butterfly valves for large diameter, low-pressure service.

Globe valves where flow throttling is required.

Body & Trim Materials:

Brass/bronze for economic small‑bore service with proper alloy choice.

316 SS for long life in aggressive or high‑temperature loops.

Seal & Seat Materials:

FKM (Viton®) for maximum chemical resistance.

PTFE for broadest temperature/chemical compatibility.

EPDM for water‑glycol mixes when oils are absent.

Design Features:

Blow‑out‑proof stems and live‑loaded packing for leak prevention.

Full‑port designs to minimize pressure drop and slush trapping.

Actuator compatibility (electric, pneumatic) matched to system controls.

System Maintenance:

Regular glycol concentration checks and inhibitor top‑ups.

Periodic valve inspection for seal wear and body corrosion.

Annual flush and refill if fluid darkens or shows microbial growth, ensuring continued brass valve chemical resistance. (FLO Control)

Verifying Compatibility & Compliance

Consult chemical resistance databases (e.g., NIBCO, Emerson ASCO) for exact mixture ratings.

Cross‑check manufacturer data sheets and confirm part numbers match rated concentration/temperature.

Field test samples in pilot loops when possible, especially for custom inhibitor packages.

Enolgas USA & HVAC Antifreeze Valve Solutions

At Enolgas USA we stock a full range of HVAC antifreeze system valves with certified materials:

DZR brass ball valves for reliable shut‑off.

316 SS butterfly valves for large hydronic loops.

PTFE‑seated globe valves for precise flow control.

Every valve carries rigorous factory testing and follow‑up audits to ensure lasting glycol valve compatibility and industrial valve compliance.

Ready to optimize your HVAC glycol loop? Contact our technical team for datasheets, compatibility charts, or on‑site consultation.

Comments